One of the most antiquated industries is about to get a modern upgrade.

To hear Don Webster tell it, oyster aquaculture technology is equivalent to something like a flail for threshing, a horse-drawn plow, maybe even a scythe. Webster, a regional aquaculture specialist at the University of Maryland (UMD) Extension, should know. He’s been studying the industry for 40 years and says that advancements in traditional bottom culture oyster planting and harvesting are essentially non-existent.

The option to farm off-bottom exists, but farmers must manage it at scale in order to turn a profit. The approach involves the production of hatchery-raised oysters in containers, which float in man-made reefs. There’s a high cost involved with the equipment and methods, which helps make traditional on-bottom aquaculture more appealing and enduring.

Meanwhile, demand for the marine mollusks continues to grow. This year’s oyster market is 1.2 million tons; recent analysis predicts that it will grow to 2.4 million annual tons by 2033. In recognition of the need to close the gap between demand and production, the United States Department of Agriculture (USDA) has funded a five-year, $10 million grant, led by researchers at the University of Maryland, to bring the industry from past to future.

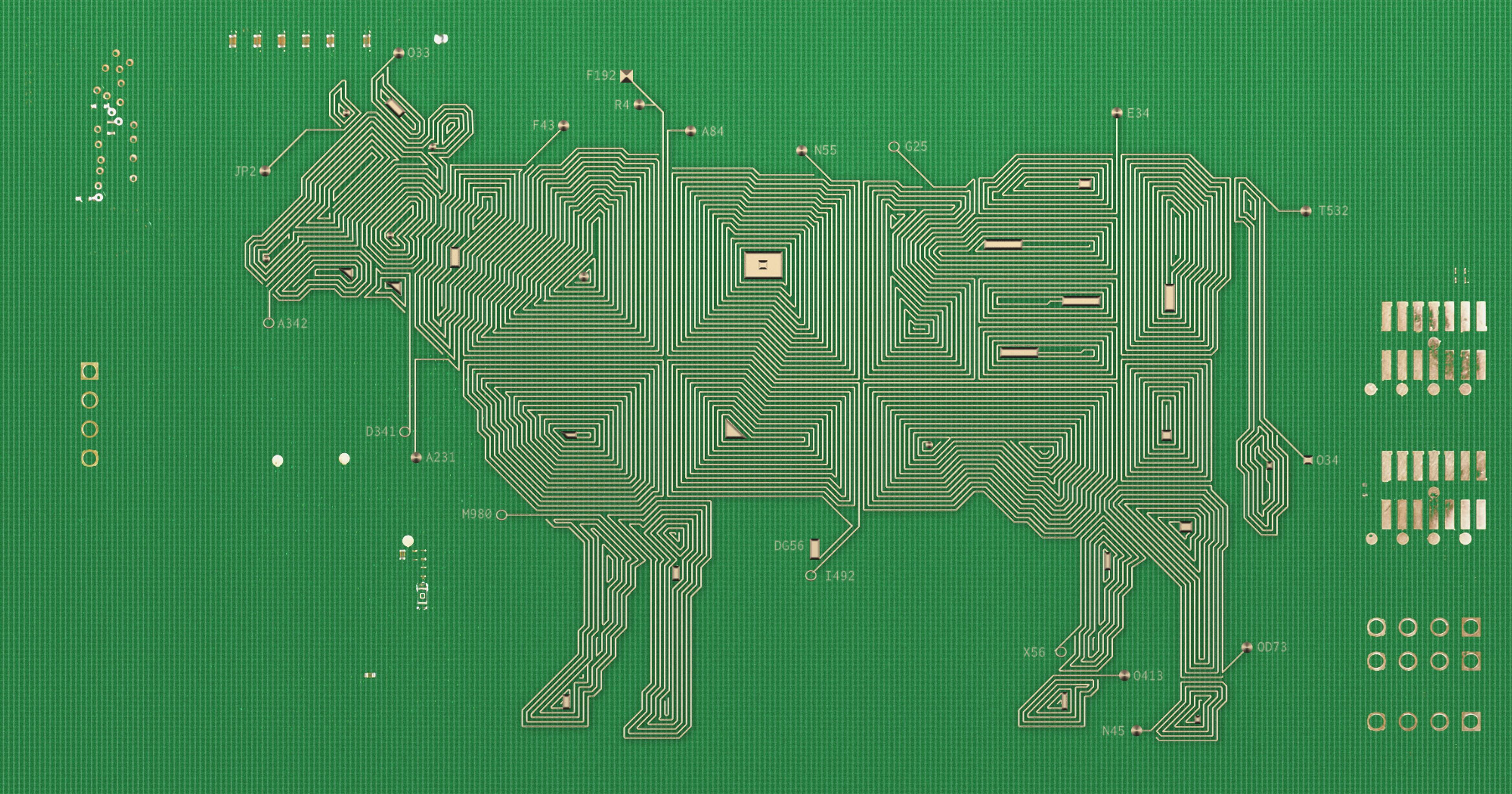

Led by Miao Yu, a professor in UMD’s A. James Clark School of Engineering, and dubbed the “Smart Sustainable Shellfish Aquaculture Management“ (S3AM) project, the multi-disciplinary/multi-institution — several UMD branches plus Louisiana State, Virginia Polytechnic Institute, the Pacific Shellfish Institute, and the Fraunhofer USA Center for Experimental Software Engineering — effort has set about to develop precision farming techniques to help increase profitability in the market. To accomplish that goal, the S3AM project is tackling the two main issues holding back progress: outdated planting and harvesting methods.

“The U.S. oyster industry currently faces significant production bottlenecks because of outdated technology and tools,” explained Yu. “We are developing and implementing a framework to enhance nationwide shellfish production and economic viability of shellfish farm operations, while maintaining environmental health.”

Currently entering its final year, the S3AM project is giving oyster farmers plenty of reasons for hope.

Problem One: Planting

Oyster farming has a long, rich history in Maryland’s section of the Chesapeake Bay — as early as the late 19th century, the state was harvesting more than 15 million bushels of wild oysters annually. By 2011, however, that number had plummeted to 0.3 percent of that abundance, thanks to overfishing, habitat loss, and disease. The state employed a cross-sectional panel of 40 experts to bring the industry back to life.

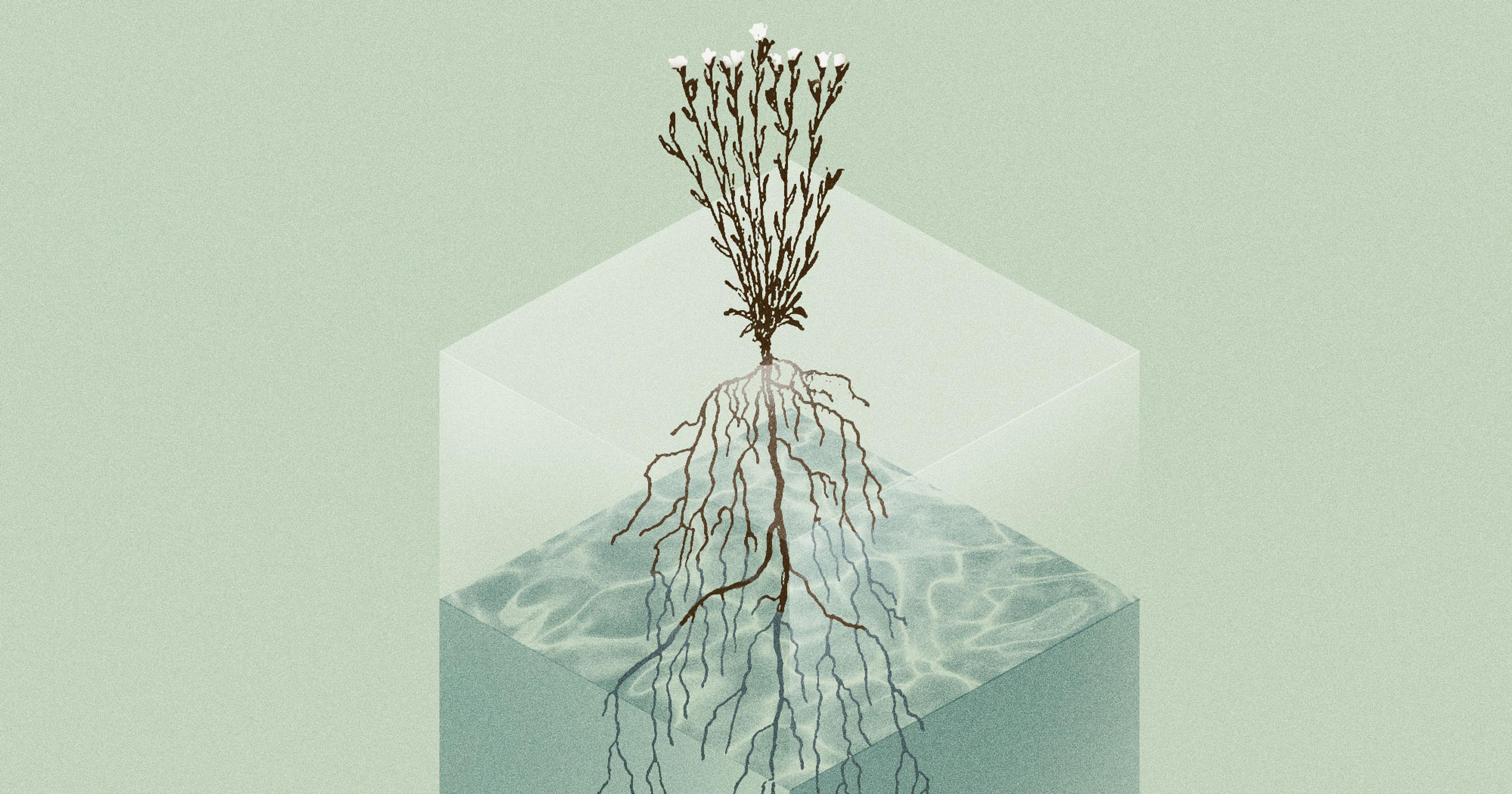

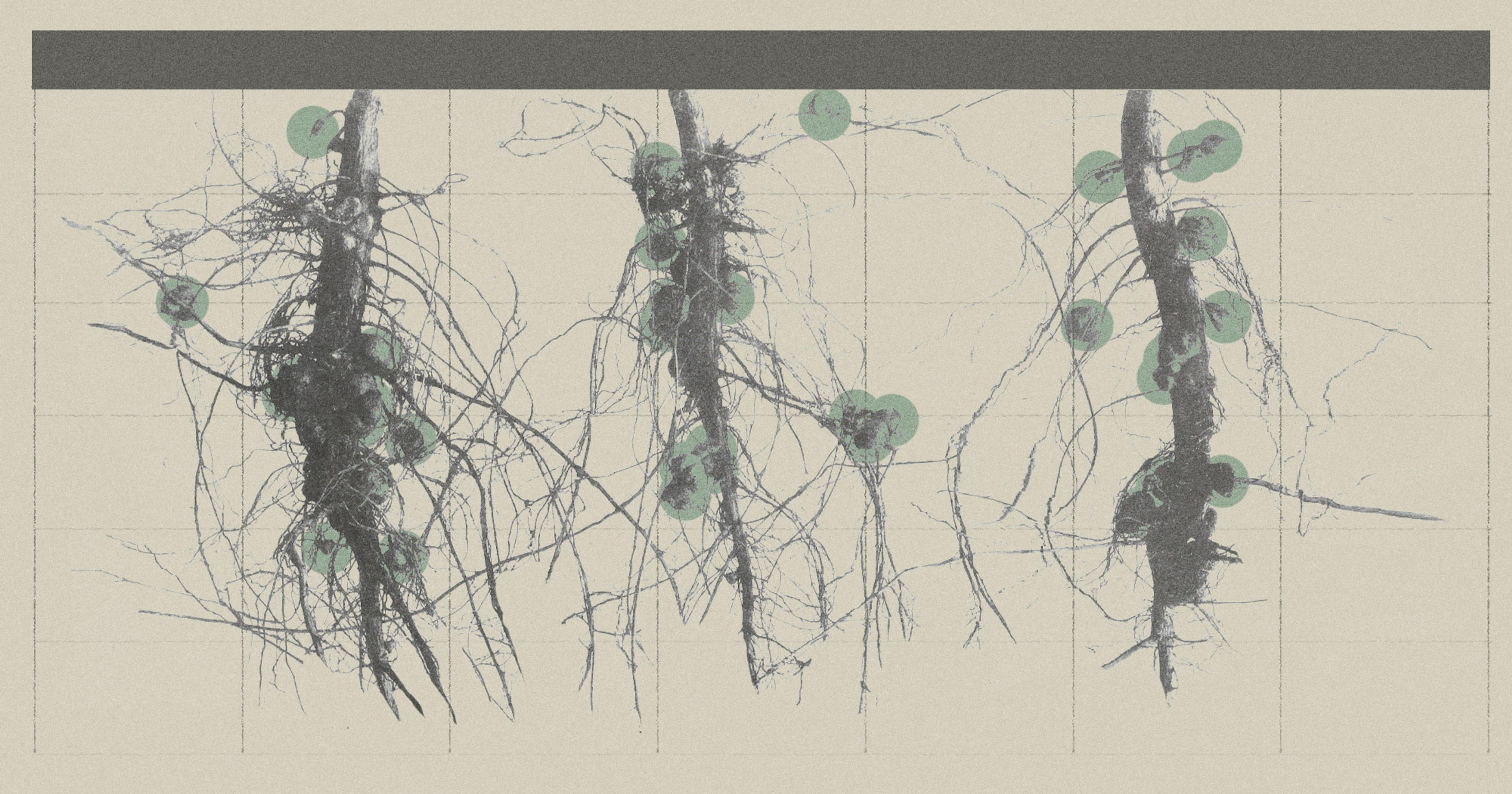

Despite a successful and concerted effort to restore the oyster populations through the Oyster Recovery Partnership, farming methods remained stuck in the past century. From planting/seeding methods to harvesting techniques, not much has changed of late. The result: “The current oyster farming starts from random deployment of spat-on-shell oyster seeds in a farm plot,” said Yu. “If the seeds land on mud, they will suffocate and die. So many young oysters are lost in the planting phase.”

While mileage may vary, a typical acre of bottom culture oyster planting will produce between 500 and 800 bushels of oysters in a three-year period, according to Webster. “There are no good tools to monitor what’s happening on the bottom in the meantime,” he explained. “Farmers don’t know the conditions of the substrate, and they can’t really see the oyster sizes or counts before harvesting.”

“There are no good tools to monitor what’s happening on the bottom.”

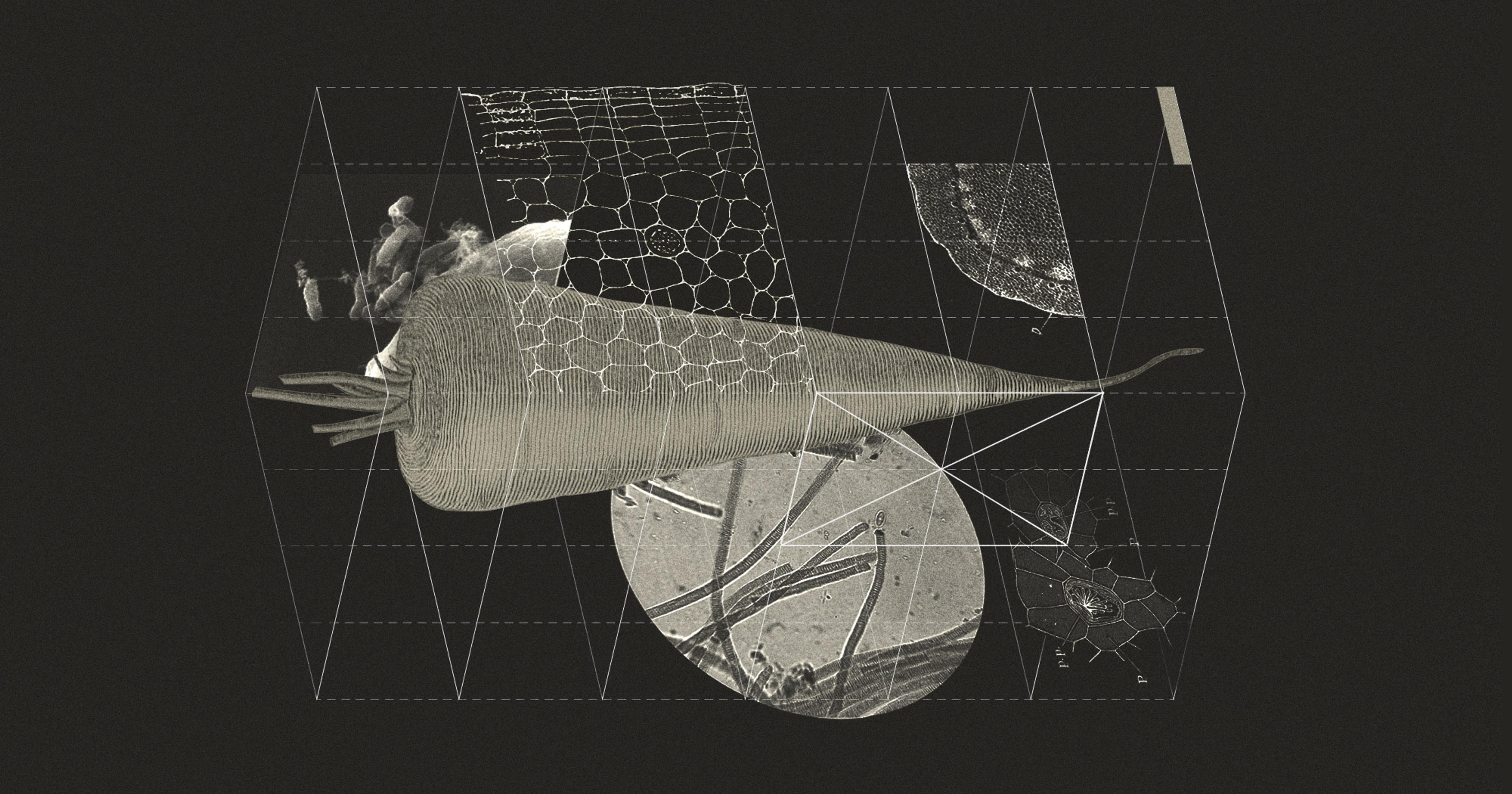

To combat those losses, the S3AM team has worked to develop an underwater, environmental monitoring system that is capable of mapping water quality and substrate conditions as well as oyster inventory conditions. Using a remotely operated underwater vehicle (ROV) with drone technology tethered to a command vessel on the surface, the S3AM monitoring tracks the much-needed information of an oyster lease. The drone collects details on the health, growth, and plant harvest beneath it by determining how many live oysters exist, what their sizes are, areas of mortality, and if there are other organisms in the area, particularly predators.

Brian Russell, an oyster farmer who owns Shore Things Shellfish in Tall Timbers, Maryland, is intrigued by the project’s possibilities. He’s been harvesting about half a million oysters each year since launching his business in 2011, primarily with the existing, traditional methods available to him. “Every year, we take samples and assess the health of the oysters, but that’s a fairly random approach,” Russell admitted. “I like the idea of using the mapping technologies so that you can be more precise when you harvest.”

Current harvesting, said Russell, requires “blindly dragging a dredge” and pulling it up every few minutes to see what you’ve captured. Often, that may not be much.

Development of the ROV and mapping technologies has taken place both in the lab, assisted by machine learning, and in the field. “We are in the process of conducting the field experiments on sonar-based oyster inventory mapping ,” said Yu. “Once the mapping technology is validated in the field experiments, we will integrate it with the smart precision harvesting techniques we are developing.”

Problem Two: Harvesting

Just as oyster planting techniques date back 200 years, so too do harvesting techniques. “After two to four years of growth, a towed dredge is used as the primary tool for harvesting,” said Yu. “Since farmers don’t have the information about where the market-sized oysters are, the dredging harvest is usually done randomly and repeatedly to increase the chance of harvesting more of the oyster crop. Dredging activity can be environmentally damaging to oyster habitat and water quality. As a result, from planting to harvesting, the survival rate is very low.”

Based on the S3AM mapping results, the team is developing path planning algorithms that will generate an optimal path for the harvesting vessel to follow. The simulation results obtained by UMD Engineering Professor Yang Tao’s group have been promising, suggesting that this precision method can greatly enhance the harvesting rate.

All told, when combined, the monitoring and harvesting techniques will ideally lead to increased efficiency, reduced time, reduced labor, and reduced fuel use. “That will be the success of the project,” said Webster.

Oyster Farmers in Training

While the S3AM project has been led by researchers and extension faculty at UMD, it has involved students and the local community to achieve its goals. The team’s education partner, University of Maryland Eastern Shore (UMES), is a historically Black institution and the team has worked to prepare undergraduate students for careers in American aquaculture. Maryland 4-H has also served as an educational partner, introducing the project via summer camp and robotics competitions.

“With a goal of promoting diversity and inclusion in science and engineering education, our education programs have helped prepare socially and economically disadvantaged and first-generation college students in rural coastal areas to become a skilled workforce in the American agricultural industry,” said Yu.

To that end, Yuanwei Jin, professor and chair of the department of engineering and aviation sciences at UMES, developed two classes for undergraduates that tie into the S3AM project. Senior capstone projects have also involved the S3AM work. “They’ve been very involved in both the hardware and the software development for the oyster imaging,” Jin said. “This has allowed the students to earn additional digital badge certificates that help them launch in the industry, as well as academia.”

As the project enters its final phase, the team is banking on success, and Russell is anxious to potentially put the tools to the test. “Any advancement in our industry is good, whether with different gear or technology,” he said. “Any time someone is interested in researching aquaculture, I’m excited.”