Agricultural transport is a significant contributor to climate change. Full electrification is a ways off, but advocates note subtle signs of progress..

Conversations about agricultural emissions often center on livestock or fertilizer. Transport is a quieter, but crucial contributor. From farm to grocery store to kitchen cupboard, there’s a sprawling network of trucks, trains, and ships working to bring your groceries to you. About 30% of the world’s GHG emissions come from land-based transport, predominantly of cargo. But, as it stands, very little of that transport is powered by electricity.

“You can’t wake up a person who is pretending to be sleeping.” said Rish Ghatikar.

The words by Ghatikar, who is a researcher and advisor to the transportation and energy industries, are momentarily puzzling — what does pretend-sleeping have to do with electric trucks? Ghatikar is a visiting professor at the University of Southern Denmark, an Open Charging Alliance Ambassador, and he consults for EV startups; he’s considered a global authority on electrifying the trucking industry.

Ghatikar uses sleeping as a metaphor to describe prevailing attitudes towards the health and environmental consequences of a fossil-fuel dominated transport industry. By pretending to sleep, he outlines how policy and industry may appear to sideline these consequences, and even miss out on economic opportunities.

In the United States, almost all food transport happens by truck; transportation accounts for one fifth of the carbon emissions of food production and consumption. Researchers are still trying to estimate the global health impact of these tailpipe emissions, but it’s significant. These emissions have high concentrations of particulate matter and harmful gases like carbon monoxide, nitrogen oxides, and sulfur dioxide, which are linked to respiratory issues or exacerbate existing ones like asthma; they can even lead to complications like heart problems.

“For me, a lot of electrification comes down to tailpipe emissions. They’re so, so harmful,” Ghatikar stressed.

On the upside, with the right infrastructure, investment, and policy alignment, he believes that electrifying agricultural transport could offer one of the fastest pathways to climate progress and human health improvements.

Decentralizing Power

Long hours, tight delivery windows, and razor-thin margins leave little room for error for long-haul truckers. Most agricultural transport happens by road, whether it be a cross-country, big-rig journey or short-haul trucks delivering from farm to distributor. Technically, any of these vehicles have potential to be electrified, but logistics vary with scale and distance. Many agricultural trucks operate in remote areas with limited infrastructure. Charging time, limited range, and sparse rural charging stations are real concerns that could disrupt already demanding schedules.

Ghatikar and his colleague Michael Barnard worked on a series of articles identifying logistical hurdles in decarbonizing the trucking industry. Barnard is the founder and chief strategist of The Future is Electric, an analytical firm.

One issue: Agriculture predominantly takes place in rural communities in the U.S. “That poses a different set of challenges for the availability of charging infrastructure. The Level 3 charging [DC fast charging for heavy-duty vehicles] requires robust electrical infrastructure for high-capacity charging needs,” said Ghatikar.

The problem is, the United States’ grid hasn’t been upgraded or modernized for the last three to four decades. Wires carrying electricity to truck stops and warehouses are often thin and overhead, prone to overloads and extreme weather events. The distribution grid is also not currently equipped to handle the additional load that fully electrified agricultural transport would demand.

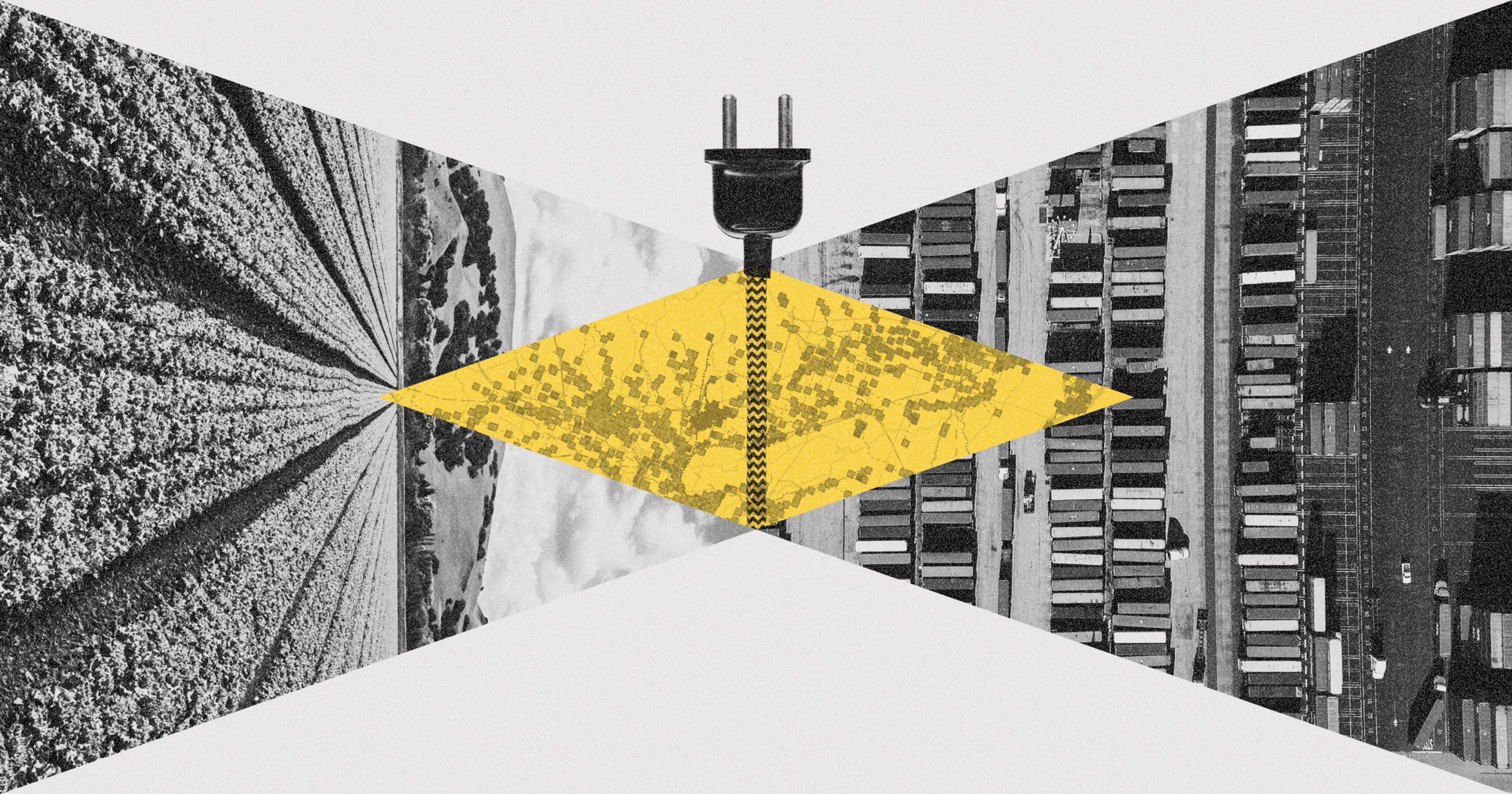

EV infrastructure like national charging stations is vital, but a centralized system that’s wholly dependent on the outdated grid might not be the best approach. A solution? Micro-grids.

A grid has three parts: An energy source where electricity is generated, a point where energy can be used, and a battery, where energy needs to be stored. Batteries help balance supply and demand, reducing strain during peak use or adding a boost when power is scarce. A micro-grid can serve just a single house, or even scale up to powering a neighborhood. They assure power availability, especially in areas prone to outages or scarcity. Ghatikar and Barnard’s model suggests deploying these microgrids wherever trucks need power, from farm to processor to rest stop. Microgrids can also address EV’s carbon problem.

“Depending on the energy matrix used to provide the energy, there might be no statistical difference in carbon emissions between using an EV and using a traditional diesel-powered engine,” said Lourival Monaco, a research assistant professor at Purdue University and research manager at Purdue DIAL Ventures, investigating agricultural economics.

The key difference is where power comes from. For example, if an electric vehicle is powered by electricity generated from burning coal, the total emissions might be the same as a gas-powered car. The key difference is simply where those emissions occur — at the power plant instead of from the vehicle’s tailpipe. One possible solution: Solar arrays could provide a significant chunk of the power required for microgrids.

“The plummeting costs of solar panels, despite the 50% tariff on Chinese panels, means that commercial solar installations at depots and truck stops are less expensive and with a faster return on investment than ever,” wrote Ghatikar and Barnard in an article in CleanTechnica.

Solar for EVs, combined with microgrids, could be something of a win-win. Farmers get electricity at minimal to no cost, and transportation runs at minimal to no emissions.

Dan Porter, director of operations and head cheesemaker at FireFly Farms Inc. at Deep Creek (Maryland), said his operation has already instituted solar panels to offset electricity costs. Currently, it doesn’t power EVs — electric trucks “are just currently way more expensive than a normal truck to purchase” — but rather helps them meet day-to-day electricity needs.

“Our grid makes about 60% of our power usage I think, but less in winter and more in summer. The array was 50% funded by a grant. [Overall] I think it was a good investment,” said Porter.

Grants, however, raise the next question. Who exactly is paying for electric trucks? Who pays to install things like microgrids?

The Right Policies

The immediate concern is that increased costs might shift to farmers and trucking companies — those costs are significant.

“A new fully electric commercial truck that you can put a milk tank body on costs 3X what a conventional diesel costs. Conventional $100k, electric $300k. There is also no used market. There are infinite used diesel trucks for $60k, but no electric,” said Porter.

It should be noted: Not all electric trucks are expensive. Smaller delivery trucks that travel relatively fixed, short distances every day already beat out diesel trucks in terms of cost. But that’s not the industry norm.

“Transportation is a tool. Processors look at this tool as an ROI-based decision. They’re going to leverage whatever makes financial sense to do — unless they can charge a premium for low carbon [products], it’s unlikely they’re going to invest in a tool that reduces their ROI,” said Monaco.

There is some concern that this premium might end up being a bad business decision.

“If you ask consumers ‘Do you think we need to have more sustainable products in supermarkets,’ over 80% will say yes. If you ask ‘Would you be willing to pay additional?’ in our research, 40% say no and 60% say yes,” said Monaco.

If consumers aren’t in a position to compensate for this extra cost of electrifying trucks, and processors see their bottom line changing, the onus of sustainability falls on the state.

In an ideal world, the extra costs of supporting farmers and transport companies that want to switch to EVs, as well as the setting up of micro-grids, would come from state, federal and local programs — a number of which do exist. One example is the USDA Rural Economic Development Program, which can provide grants of up to $2 million dollars to fund EV charging stations. The Bipartisan Infrastructure Law and Inflation Reduction Act also contained pro-EV and grid policies in the form of tax credits and discretionary grants. And many states have a dizzying array of funding, too. Virginia, for example, allocates grants specifically for EV provisions in rural communities. Washington state deployed $85 million in grants during 2024 to build thousands of chargers.

And it’s not just direct funding that can help. When asked about what policy changes might enable electrification, Daniel Sperling laughs for a good 10 seconds before responding. “There are more than I can count, probably,” he said.

Sperling is the founding director of the Institute of Transportation Studies at the University of California, Davis, and a leading international expert on the energy and environmental aspects of transportation. Sperling outlines a number of non-grant-based policy shifts that could be implemented. Equipment manufacturers can pass on costs to final purchasers. Manufacturer mandates to sell a minimum number of electric vehicles can reduce prices for purchasers. Scholarships can be given to train new EV mechanics and maintenance staff.

“With policy changes, it’s vital to articulate benefits and be clear about potential outcomes, and be clear about the potential challenges that must be overcome,” said Ghatikar.

A circular economy of EVs can also help reduce costs. Batteries remain the most expensive part of an EV. For a personal vehicle, a 25% loss in battery capacity typically signals the need for a replacement. Instead of replacement, electric batteries or EVs themselves can be resold to less strenuous sectors, or deployed on shorter routes, recouping some costs.

From incentives to lower prices to battery swapping to rebates, there are ways to electrify the industry — but is there a will?

California-based Challenge Dairy purchased two EVs for their regular delivery route, and reached out to Offrange for a potential profile. But as the current administration announced changes in electrification policy, they rescinded this offer.

Changes to policies and subsidies currently involve a major rollback of the previous administration’s pro-EV policies. An important Biden-era goal was a (non-binding) agreement for 50% of vehicle sales to be EVs by 2050. The Trump administration has issued an executive order to dismantle this goal. They have also frozen the $5 billion National Electric Vehicle Infrastructure (NEVI) Formula Program for building EV infrastructure earmarked under Biden. The Inflation Reduction Act also supported the expansion of the USDA’s $1 billion dollar support for rural farmers to access clean energy — the Trump administration froze this funding. All of these changes can be understood in the context of the administration’s executive order from January 2025, “to eliminate the ‘electric vehicle (EV) mandate’ and promote true consumer choice.” A lot has also changed with the passing of the “Big, Beautiful Bill” on July 4th.

Slow Steps Forward

In 2021 and 2023, the California Air and Resource Board proposed two ambitious plans to transition a significant proportion of medium and heavy duty vehicles to electric, eliminating fossil fuels. Some agricultural and trucking organizations expressed unease, and the state has since withdrawn the requirement for comprehensive fleet electrification.

The state also requested a waiver from the U.S. Environmental Protection Agency to implement these emission standards, but repealed this request earlier this year.

“Identifying priority areas — both geographies and sectors, is key to begin the transition to EVs,” said Ghatikar.

For geographies, the agricultural powerhouses of California, New York, the Midwest, and Great Lakes regions are key. A lot of transport happens within these regions, minimizing the range required for EVs, and thereby reducing costs.

Among ag sectors, dairy production looks particularly promising. Dairy transport is always refrigerated, and around 15% of global fossil fuel energy is used in refrigeration.

“An electric refrigeration unit drawing from the battery could be 85-90% efficient overall,” said Ram Vijayagopal, research engineer at Argonne National Laboratory.

Most farms are within a 125-mile radius of a dairy processing facility, and data demonstrates that refrigerated tankers usually drive less than 300 miles a day. Strict labor laws surrounding the number of hours truckers can drive means they spend a lot of time doing other activities like loading, unloading, and resting. Since processors typically organize transport, a charging station at just one pickup point could provide enough charge for a truck to easily complete a day of driving. Coordinating charging with milk transfer means truckers won’t even lose time.

Whether electrification starts with dairy or not, the steps to enabling decarbonization of agricultural transport are clear. Solar-powered microgrids for charging, policy interventions, and research to lower costs, and rolling them out slowly in the sectors and geographies that will benefit the most. The real question is, will we wake up? Or pretend to keep sleeping?

Correction: This article initially stated that 15% of global emissions came from refrigerated transport. That figure includes all forms of refrigeration, not just from the transportation industry.