Researchers are exploring many ways to produce ammonia-based fertilizer without using fossil fuels — even pulling it from thin air.

Morris, Minnesota, a small city surrounded by farmland, is flanked to the north and south by two wind turbines. Stretching 82 meters across, their blades harness the gusts of wind that sweep across the city, and bring that energy to a modular building on the University of Minnesota’s West Central Research and Outreach Center (WCROC). There, it powers the process to create a low-carbon ammonia that’s used to make fertilizer.

“It’s an elegant concept when we thought about it,” said Michael Reese, the Renewable Energy Director at WCROC. “That you could have these wind turbines on farmers‘ land, and then they could produce a product that could be used on the fields right below the wind farms.”

When the pilot project went online in 2013, it was the first in the world to use wind energy to produce ammonia. Since then, dozens of projects have sprung up across the globe that aim to make lower-carbon “green” ammonia, most of which is used for fertilizer.

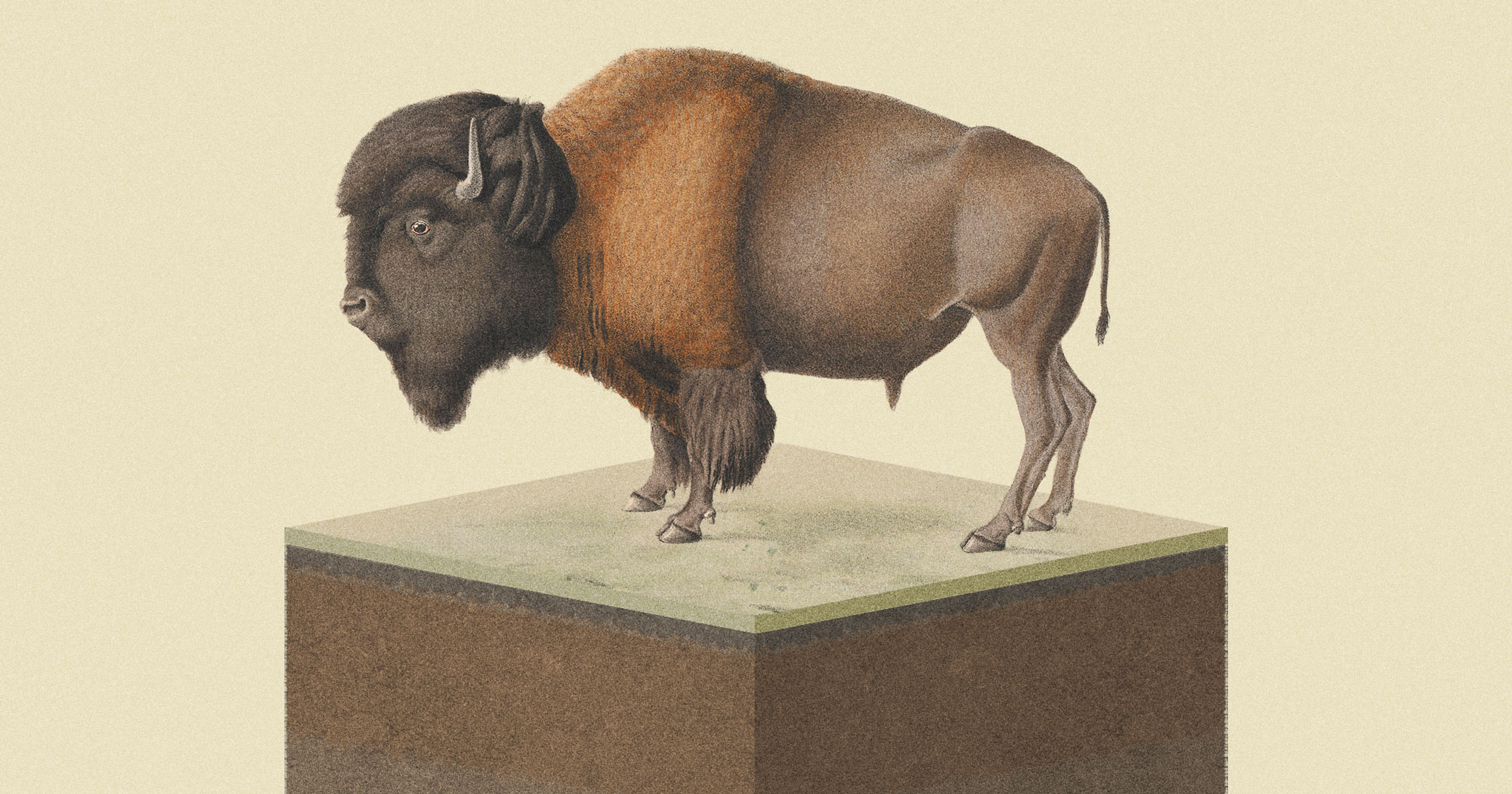

Ammonia is a vital component of the nitrogen fertilizer industry, and its production currently accounts for about 1.8% of the world’s carbon emissions each year. One study found that swapping in green ammonia could reduce the carbon footprint of corn by 33% in the Corn Belt, without requiring farmers to make changes to their current practices.

Along with slashing emissions, supporters say localized green ammonia plants could help shorten supply chains and stabilize prices in an industry known for its volatility. “You could decarbonize agriculture, have security of supply for nitrogen fertilizer, cut down the risk associated with transport, and keep dollars in our local communities,” said Reese.

But creating green ammonia in a way that’s efficient and cost-competitive isn’t straightforward, especially since fossil fuels are conventionally used in multiple parts of its production.

“Ammonia has been manufactured pretty much with the same process over the last 100 years or so,” said Lea Winter, professor of chemical and environmental engineering at Yale University. “It’s an interesting scientific challenge to figure out how we can make a better process compared to the one that’s been around for 100 years.”

Swapping Natural Gas for Water — and Price Stability

The first step in making ammonia is to produce hydrogen, usually by extracting it from natural gas or coal, which releases carbon dioxide. After that, the hydrogen is combined with nitrogen from the air at a high temperature and high pressure to produce ammonia.

The second part of the process tends to require a lot of energy and is most efficiently done at a large-scale, which is why traditional ammonia plants are big industrial operations, according to Winter. In the short term, the easiest way to slash emissions when making ammonia fertilizer is to focus on the first step and change the way the hydrogen is made.

“Ammonia has been manufactured pretty much with the same process over the last 100 years or so.”

“An attractive, more sustainable approach is to use hydrogen coming from water, typically through water electrolysis,” said Winter. Then, the rest of the process stays the same.

That’s what the Minnesota researchers did for their pilot plant. Reese said that removing natural gas from the equation has a huge impact on price stability.

“Farmers are subject to current market swings on ammonia, and the general consensus is that almost 90% of the cost of conventional ammonia is from natural gas. When natural gas goes up, so does ammonia,” he said. The price of ammonia fertilizer in the U.S. has ranged from about $500 to $1,600 per ton over the past 5 years.

Renewable energy contracts, on the other hand, tend to be for longer periods of time, usually at least 10 years to upwards of 25. That means companies can offer green ammonia at a consistent price, according to Reese. In 2024, long-term contracts for green ammonia in the U.S. Gulf Coast were about $600-$800 per ton.

“If you overlay the price of conventional ammonia and how volatile it is, basically you find that green ammonia will be kind of right in the middle. And so sometimes it’s cheaper, and sometimes it’s not, but it’ll be more stable,” said Reese. “It’s an advantage that farmers can budget, and then they can market their grain, their crops, accordingly. Whereas, if you don’t know what the fertilizer prices are going to be in the spring, how do you manage that essentially?”

“So sometimes [green fertilizer] cheaper, and sometimes it’s not, but it’ll be more stable.”

On top of price fluctuations from natural gas, the fertilizer supply chain is also notorious for its volatility, and farmers in the U.S. have experienced disruptions in recent years from both the war in Ukraine and drought along the Mississippi. Stakeholders have also raised concerns about the long-term sustainability of phosphorus, another key nutrient in fertilizer.

The desire to provide locally produced, affordable fertilizer to farmers is what inspired Hiro Iwanaga to start TalusAg, a company that manufactures and deploys modular green ammonia systems.

TalusAg’s first project was in sub-Saharan Africa, where supply chains are even more tenuous and farmers pay significantly more for fertilizer. At the Kenya Nut Farm, the modular system uses on-site solar panels to produce hydrogen from water instead of natural gas.

“Access to reliable and affordably priced fertilizer is absolutely paramount to any farmer,” said Iwanaga. “Because our systems can locally produce that basic fertilizer, we can avoid what can be a 10,000-kilometer-long, expensive, unreliable supply chain.”

“Access to reliable and affordably priced fertilizer is absolutely paramount to any farmer.”

But he soon recognized there was a market in the U.S. too, in part because of the falling cost of renewable energy and the government’s clean hydrogen manufacturing tax credit that went into effect in 2022. “We are cost-competitive in the United States because we have the clean hydrogen production tax credit. In the rest of the world, we’re cheaper because their logistics costs are just so much higher,” Iwanaga said.

The tax credit is set to expire in 2027, but will cover any projects that have started construction before then.

TalusAg recently began operating a green ammonia production system in Iowa in partnership with a local agricultural cooperative, and has plans to open 74 more in the U.S. over the next few years, focusing on locations like South Dakota and Arizona, where fertilizer costs tend to be higher. Each of their modular units can produce about 7,000 tons of ammonia per year, with some sites having up to seven units on them.

“We deploy projects only when we can be cheaper, more reliable, and more sustainable,” he said.

Reinventing the Other Part of the Process

Though swapping natural gas for water to make hydrogen and powering that process with renewables is one way to make lower-carbon ammonia, other scientists are working on reinventing the second half of the process.

That decades-old procedure is known as the Haber Bosch process, during which nitrogen and hydrogen react at high temperatures and pressure. It’s very energy-intensive and hard to scale down in an efficient way.

A research team at Stanford University recently created a prototype device that uses a different process, producing ammonia by drawing air through a catalyst-coated mesh, with the nitrogen and hydrogen coming from water vapor.

It operates at room temperature, standard atmospheric pressure, and relies on microdroplet chemistry, the idea that “little water droplets or air bubbles in water are highly reactive at the interface,” according to Richard Zare, professor of physics at Stanford.

“I would like ... when the farmer waters his or her crop, what comes out contains fertilizer dissolved already in the water.“

The initial prototype produced enough ammonia to work as a hydroponic fertilizer in a greenhouse setting, but more work is needed for it to scale up and become market-ready. “I would like to be able to put it into farmer’s hands, in a way that when the farmer waters his or her crop, what comes out contains fertilizer dissolved already in the water,“ said Zare. ”That, to me, would be ideal.”

Other approaches have the same idea. Lea Winter, the Yale professor, is most excited by a method that uses plasma technology to create fertilizer. The plasma reactor acts like a controlled “low-temperature lightning” strike to create the reaction, and only needs air, water, and electricity for the process, she explained.

“It allows us to be able to directly take air, water, and renewable electricity and turn it into fertilizer compounds in water,” Winter said. “It’s something that we’re still discovering a lot about, but it opens up a lot of opportunities.”

There are several startups focused on this technology, and one group of researchers found that it increased tomato plant growth. Still, others are looking at methods to use human wastewater as fertilizer, since it’s high in nutrients like nitrogen.

Beyond carbon emissions from the production process, ammonia fertilizer also has other negative environmental impacts during its application. Up to 60% of the fertilizer applied can get lost to the environment, contaminating the air and groundwater, and harming aquatic life.

“Being able to make ammonia is really essential for food security.”

“Instead of going into the plants to help them build up plant matter and make food, it ends up in the air or lost to the soil, lost to the water, and then ends up contaminating groundwaters,” said Winter.

She said part of that is because synthetic fertilizers often get applied in excess. “If you have these concentrated, solid fertilizers that you’re purchasing that are delivered to your farm, and you’re only able to apply them a couple times a year, then that leads to this over-application and the resulting waste,” Winter said.

Winter said she hopes some of the localized innovations, like diluting ammonia in water and spreading it through irrigation systems, could help apply ammonia fertilizer more efficiently and on-demand, leading to less waste and environmental pollution. Other ways to reduce synthetic fertilizer use include planting cover crops, no-till farming, and using natural methods like compost.

“Being able to make ammonia is really essential for food security,” said Winter. “It’s this important challenge where you can make a lot of impact in terms of mitigating carbon emissions. And if we could come up with a process that can be more accessible to global populations, where you don’t need to have the capital to build an enormous new ammonia plant, or figure out how to break through challenges with transportation networks, then you could also have a big impact on augmenting food security.”