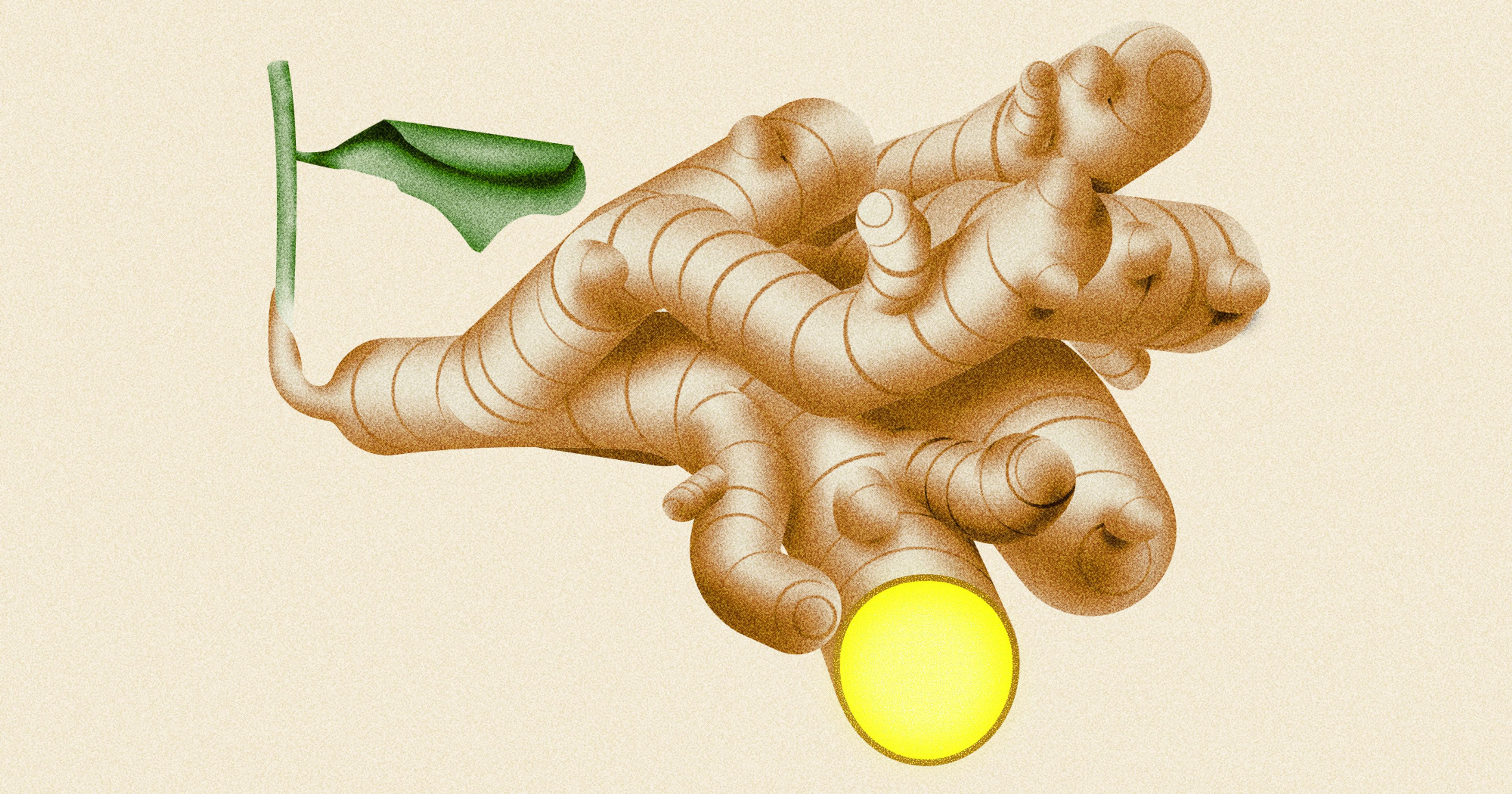

Ramps, aka Appalachia’s wild leeks, are a highly coveted seasonal commodity. What will it take to get more people growing them?

There may be no such thing as a stupid question, but there are certainly unobservant ones. Consider the newspaper reporter, standing among Jeanine Davis’ tidy rows of ramps in Western North Carolina, who asked if it was impossible to cultivate the pungent native leeks.

It was the early 2000s; Davis, a horticultural scientist with North Carolina State University, and her colleagues had recently planted some of the country’s first ramp research plots. “We’re just cracking up,” she recalled. “We’re going, ‘Yeah, Mother Nature put them in these little square beds!’”

In the reporter’s defense, ramps have long carried a wild mystique, which has only intensified in recent years. The emergence of their broad green leaves from the forest floor in late March or early April marks the start of spring, and diggers traditionally forage them from jealously guarded patches in the woods. Appalachian communities like Richwood, West Virginia, and Waynesville, North Carolina, host annual celebrations known as “ramp feeds,” where hungry guests eat hundreds of pounds alongside ham and beans.

Now, thanks to attention from celebrity chefs like Martha Stewart and Rachael Ray, ramps have morphed from regional oddity into hot commodity, with consumers far outside Appalachia paying up to $40 per pound during their limited season. Due to the distributed, often informal nature of ramp sales, Davis said it’s impossible to gauge the true size of the market, but she’s seen demand increase substantially since she started studying the plant. (One 2021 survey by Pennsylvania State University graduate student Cathryn Pugh found a dozen commercial harvesters in Northern Appalachia alone, each foraging between 3,000 and 7,200 pounds annually for sale into major urban centers like New York and Philadelphia.)

Given their lucrative prices and worries about overharvesting from the wild — research by the U.S. Department of Agriculture indicates wild Southern Appalachian populations have slightly declined over the last two decades — ramps seem like a perfect crop for enterprising growers. Davis and others have shown that ramps flourish under forest farming, where a deciduous tree canopy lets in spring light but keeps the soil cool and moist throughout the summer.

Yet farmed ramps remain vanishingly rare. Online direct-to-consumer outlets like Marx Foods and D’Artagnan advertise the wild provenance of their ramps. Mountain Food Products, which serves restaurants throughout the foodie destination of Asheville, North Carolina, contracts with area foragers. Why the mismatch between demand and cultivated supply?

Part of the challenge, explained Davis, is the slow and finicky growth of ramps from seed. While ramp seeds are broadly available from national distributors such as Fedco and Everwilde Farms, they require alternating warm and cold periods to break out of dormancy and can take up to 18 months to germinate. Even under optimal conditions, producing a harvestable bulb from seed takes at least five years, and usually closer to seven.

That means prospective ramp farmers generally look for already established bulbs to jump-start their own operations. Over time, those bulbs will split and produce new plants, just like domesticated onion sets. And once a patch gets established, that asexual reproduction assures a regular annual harvest, assuming the farmer leaves enough ramps behind each year.

“I can fit a couple years of supply in my little tenth-acre shade garden because they can be planted so densely.”

But as with other high-value woodland plants like ginseng and goldenseal, it’s very hard for forest farmers to find commercial quantities of ramps suitable for transplanting. There’s limited economic incentive for plant nurseries to grow out ramps: “You’re probably going to make more money selling them as individual plants or small bundles, as opposed to planting stock,” said Margaret Bloomquist, Davis’ colleague at N.C. State.

Aware of this bottleneck, the Appalachian Regional Commission awarded N.C. State and other partners more than $490,000 last year to develop the forest farming supply chain. “Hopefully we’ll find a way for that nursery industry to be profitable enough that people want to do that part too,” Davis said.

One of the few current bulb purveyors is Devin Bachelder, who operates Gates Hill Farm in northern Vermont. He sells through RampFarm.com, the business he purchased from West Virginian ramp pioneer Glen Facemire in 2020.

The ramp business is a side hustle for Bachelder; he works in the finance department of a local hospital, as well as manages 4,000 tapped maple trees for syrup production. But it’s a bustling one: He’s sold about 20,000 bulbs per year, the limit of what he can supply given his other jobs, with customers paying $90 per bag of 100.

At this point, the majority of Bachelder’s product is still foraged, primarily from the forest floor beneath larger maple sugaring operations. His long-term goal, however, is to establish “a self-sustaining ramp production operation,” with all of his seeds and bulbs grown at Gates Hill.

Bachelder said ramp farming requires a lot of patience but surprisingly little land. His main nursery beds take up about a tenth of acre under artificial shade, and he’s prepared about an acre where those bulbs will be transplanted once they get bigger.

“Fewer ramps per pound, more ramps in the ground” is the slogan he hopes consumers take to heart.

“I can fit a couple years of supply in my little tenth-acre shade garden because they can be planted so densely,” he explained. “It’s incredible how dense ramps are able to grow. You’ll see them in their clumps in the forest, and there can be 40, 50, 60 ramps growing in one square foot. Imagine an acre of that.”

The farmed ramp supply chain may take years to emerge, but Eric Burkhart suggests that thinking in strict terms of foraging versus cultivation misses a big opportunity. A professor of ecosystem science and management at Penn State, he advocates for what he calls “a traditionally informed Indigenous perspective around ramp management” — in other words, foragers helping wild populations to grow and spread.

A managed wild harvest might look like transplanting a few bulbs from one patch to new suitable habitats in the woods, Burkhart said, or judiciously thinning out populations to encourage more genetic diversity from seedlings. He also stresses the importance of waiting until later in the season to harvest, when individual bulbs have had the chance to store more energy for reproduction. “Fewer ramps per pound, more ramps in the ground” is the slogan he hopes consumers take to heart.

It’s a message that works for Steven Goff, the owner and executive chef of Tastee Diner in Asheville. He prefers the more intense flavor of bigger ramps and often incorporates them into condiments like pickles, chimichurri, and green goddess dressing.

Goff added that, while he’d be willing to give farmed ramps a try, there will always be a certain culinary allure to the wild product.

“It feels right,” he said. “When you’re making Southern food, every aspect of it you want to feel like Mama, or that natural state of being that we were in before the super-commercial commodification of everything.“