The U.S. is the world’s top importer of vanilla beans, but American production has been minimal — until now.

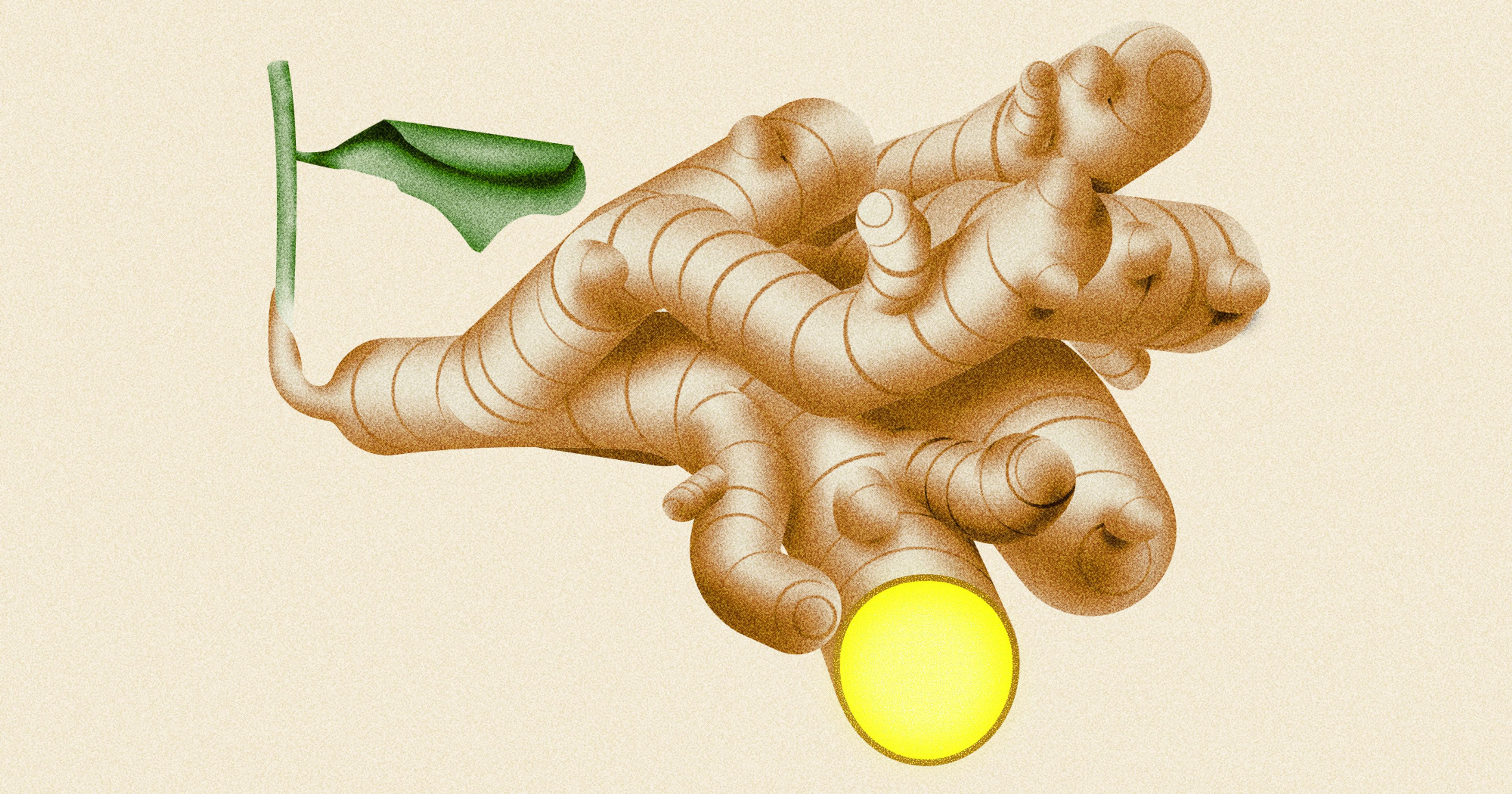

Anybody who’s taken a stroll down the baking aisle knows how valuable real vanilla — not the low-rent imitation stuff — is. Whole vanilla beans can fetch anywhere between $6 and $8 each, and more if they’re organic. That’s a premium price that most American farmers aren’t able to capitalize on, since vanilla orchid vines require tropical environments with high temperatures and humidity in order to thrive.

Today, the vast majority of vanilla comes from Madagascar — responsible for producing more than 75% of the global supply, and where smallholder farmers have gotten “richer than their wildest dreams” in recent years — followed by Indonesia, China, and Mexico. Very little of the niche crop is grown in the U.S., the world’s largest importer of vanilla. Any existing American vanilla farms are in Hawaii. But a group of Florida researchers and growers see a greater potential for establishing domestic vanilla cultivation in other subtropical regions such as southern Florida, Puerto Rico (where vanilla grew until the 1950s), and the U.S. Virgin Islands.

“Growers, especially in South Florida, are always looking for the next big thing. They’re not your typical row crop growers. The cost of the land and labor is so expensive in South Florida that to stay profitable, a lot of these growers [rely on] super high-quality specialty crops like mangoes, avocados, and rare Asian vegetables,” said Alan Chambers, assistant professor of tropical fruit genetics and breeding at the University of Florida (UF), and one of the lead researchers pushing to establish a domestic vanilla industry. “Vanilla fits into that niche. Except vanilla has that global appeal. We can never grow enough of it as a planet.”

Cultivating a domestic vanilla supply is not only good for farmers, but for consumers, too. In 2017, a combination of climate change and extreme weather events in Madagascar, as well as the rise in crime and exploitation that followed the country’s big economic boom, drove the price of vanilla to record highs. Building a supply chain that avoids imports could help alleviate some of that volatility in the future.

Clinical aromatherapist and botanical formulator Stephanie Webb sources plants of all kinds from farmers around the world. “Anything I can get domestically eliminates a headache,” said Webb, whose past struggles with sourcing organic vanilla led her to launch Sunshine State Vanilla, a wholesale supplier of vanilla plants and beans, in 2020. “Sourcing vanilla stateside means the shipping could be within a couple of days instead of having to plan weeks in advance.”

Developing a local vanilla supply chain might not seem like a high-priority mission at first. After all, it’s not a crop that will solve world hunger. But it is a ubiquitous staple ingredient used in everything from baked goods to beauty products to prescription medicines. Last year, the U.S. imported $338 million worth of vanilla for its food and beverage, cosmetics, and pharmaceutical industries. Shoring up the vanilla supply chain would not only drive costs down, it could help minimize risk to the American companies that depend on a steady supply of it.

“If there was no vanilla tomorrow, no one would starve,” said Chambers. “But when Madagascar has a major weather event, like a cyclone or hurricane, that will send our prices through the roof because supply drops. Who that hurts is the American consumer, because either they can’t get natural vanilla extract or the prices are really high and that has knock-on effects for everything else, for all those products that bring a little joy to our plate — the desserts, ice cream, even pharma and cosmetics.”

“Growers, especially in South Florida, are always looking for the next big thing. They’re not your typical row crop growers.”

To make even the tiniest dent in the vanilla supply chain, however, there first needs to be enough planting material available to American growers. “There’s a lot of excitement all over the value chain for domestic vanilla. The biggest problem, though, is you can’t just get plants, put them in the ground, and harvest,” said Chambers. “If you want to buy hundreds of acres of apple trees or citrus or whatever, there’s a place you can go because those markets have been developed.” That’s not the case with vanilla, clippings of which you won’t find at your local nursery — at least not yet.

At UF, Chambers and other researchers are leading several research projects that aim to develop high-yielding, disease-free vanilla cultivars. “We’re trying to figure out which DNA lends itself to better quality beans — longer beans, more aromatic beans, and more disease-resistant plants — so that the plants can take care of themselves,” said Chambers.

That’s been an especially challenging task because of the limited genetic material he has to work with. While all real vanilla is safe to consume — beware of global counterfeits — the FDA mandates that the term “vanilla beans” can legally only be used for those derived from Vanilla planifolia and Vanilla tahitensis plants, despite there being over 110 different vanilla species. This federal standard of identity was established in the 1960s in response to adulterated vanilla — a problem that still exists today. Chambers believes this definition is “a little too narrow,” an oversight that “left out aromatic species that have been used for centuries in North, Central, and South America.”

Cultivating a high-quality vanilla bean can be an arduous task. What we call a vanilla bean is actually a pod-shaped fruit that grows on a climbing orchid vine. Outside of Mexico, where the plant originated and where it has native pollinators, orchid flowers need to be pollinated by hand. The pods, which don’t grow until the vine is several years old, require an additional 9-10 months before they can be harvested, at which point the green pods undergo a 3-4 week curing process to become the pricey black and shiny beans we know them to be.

“There’s a lot of excitement all over the value chain for domestic vanilla. The biggest problem, though, is you can’t just get plants, put them in the ground, and harvest.”

To help streamline the process, Florida researchers are working to develop best growing practices for these vanilla cultivars, including recommendations for inputs, native pollinators (so the orchids don’t need to be pollinated by hand), and farming techniques. There are two main ways to grow the crop. For growers looking to maximize the output of their land, shade-house cultivation is recommended. “Most people, especially in Florida, are looking for this high-density production. Because even a small amount of land can be profitable with vanilla,” said Chambers.

Vanilla vines also thrive in an agroforestry system, where the vines grow up existing trees — a low-input, low-output growing method that is arguably more sustainable, albeit less fruitful. “You can use an existing mango or avocado or other fruit tree to grow your vines, and then you’ve got two crops, and vanilla becomes a secondary crop,” explained Chambers. For Florida orange groves afflicted with citrus greening disease, for example, intercropping with vanilla could help ensure those acres remain profitable.

It’s still too early to measure the potential success of vanilla in Florida. Some of the first commercial plants were put into the ground in 2018, and it usually takes five to seven years to ramp up pod production. But early projections look promising — and profitable. According to Chambers’ calculations, a Florida farmer can turn a profit on vanilla even if they sell it at $150 per kilogram, far less than Madagascar’s set export price of $250 per kilogram. The vanilla crop “would still be producing more than twice as much [gross income] per acre compared to things like passionfruit and strawberries, which are some of our highest grossing commodities per acre,” he said.

Webb estimates she’s sold vanilla vines to somewhere between 75 and 100 different growers — a diverse group of people that includes everyone from first-generation farmers to seasoned growers, as well as former airline pilots and lawyers. “I’m still shipping to new farmers every day,” said Webb, who looks forward to the day when she can source real vanilla ingredients without having to go overseas. “Having it stateside is just massive. It could definitely change the dynamics of vanilla trade.”