The newest methods of early disease detection for crops use the plants themselves to help recognize and diagnose problems — before it’s too late.

In south-central Nebraska, Brandon Hunnicutt is trying to stave off an attack.

He’s heard the reports: sightings of white mold in the Northeast and in South Dakota. He knows the fuzzy fungus is coming for his soybeans. He just doesn’t know when.

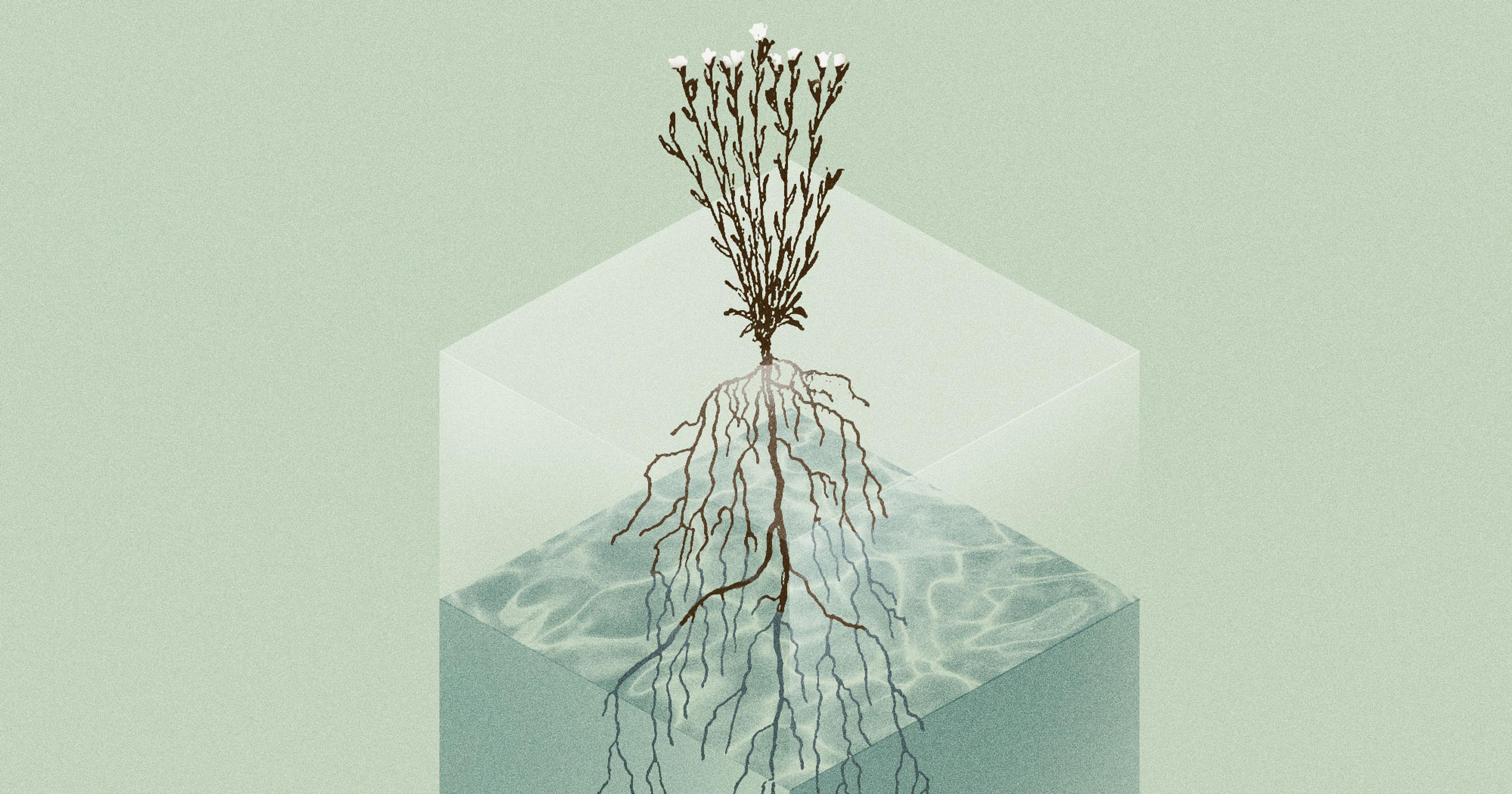

Hunnicutt is a fifth-generation farmer, who runs an irrigated farming operation on land that’s been in his family for nearly 125 years. Working with his father and brother, they grow corn, popcorn, and soybeans. Rather than guessing when crops might get sick, Hunnicutt’s now letting the soybeans “speak” for themselves.

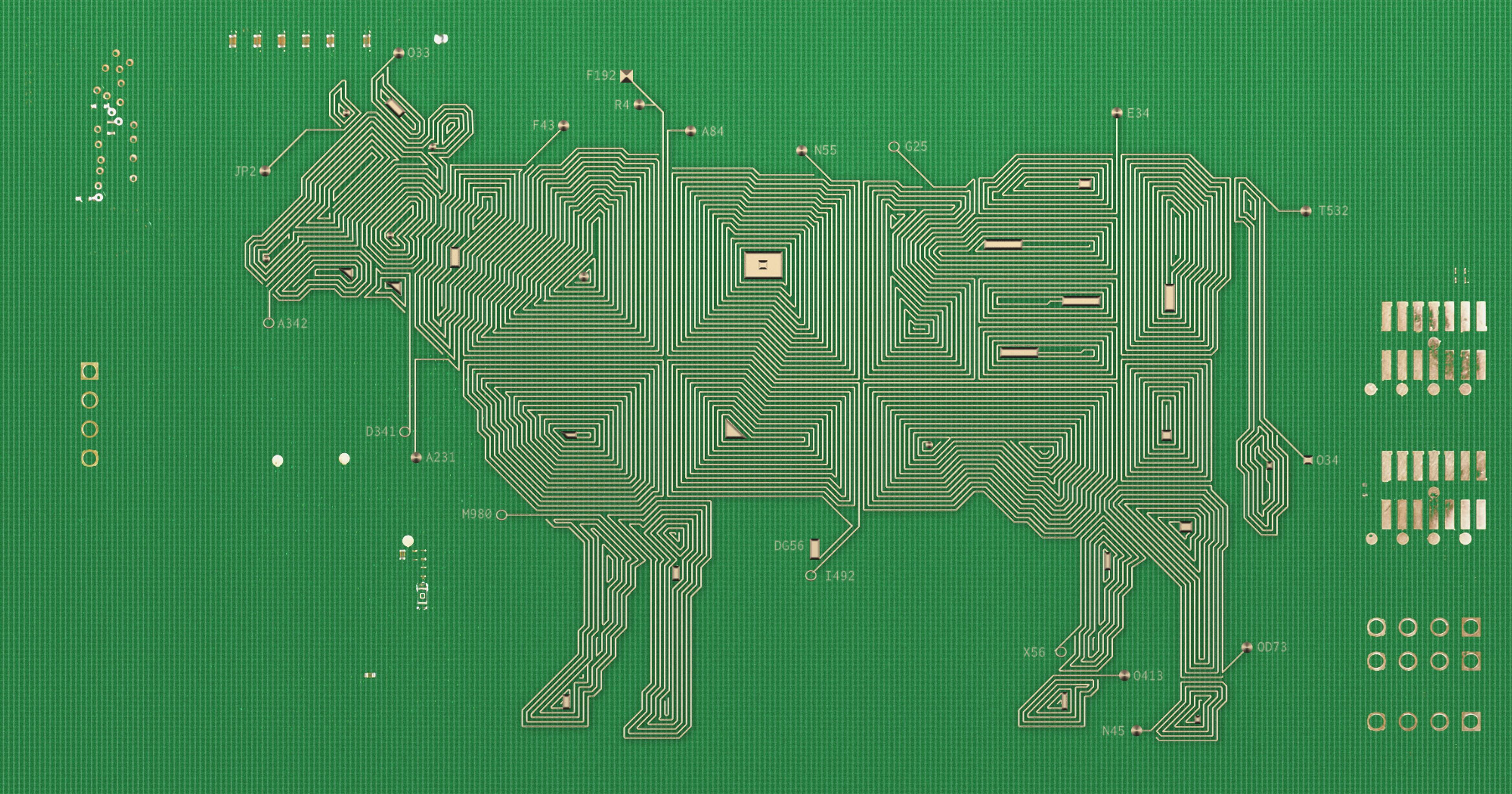

The translator, in this case, is InnerPlant, an agtech company in Davis, California. The startup engineered a soybean to emit a fluorescent signal within 48 hours of fungal infection and two weeks before visible symptoms would typically appear.

“If the plant itself can act as a sensor, that changes the game,” he said. “Usually, we’re behind the disease. By the time you see symptoms, yield’s already lost.”

The impact, of course, is bigger than any one farm. Fungal infections pose a major threat to crops worldwide, putting food supplies at risk. This is why scientists around the world are going straight to the source — the plant itself — to detect stress early. Researchers from several universities in India and Israel envision a tech-driven future where farmers beat blight using multi-omics research to reveal early warning signs, portable biosensors for quick field tests, and AI to break down complex imaging data.

“By continuously advancing and integrating detection technologies, researchers can make significant strides in mitigating the impact of these diseases on crop yields and safeguard them,” the authors wrote.

Still, size matters when it comes to adopting agtech, including early warning systems. A McKinsey study found that farms over 2,500 acres are 45 percent more likely to invest in agtech than smaller operations under 100 acres, mainly because they can spread out the costs. Even when input prices drop, tight margins mean any new made-for-growers technology has to save money or boost yields fast. Ideally both.

“Usually, we’re behind the disease. By the time you see symptoms, yield’s already lost.”

Add climate chaos to the equation, and the urgency ramps up. In hard-hit regions like Europe and Latin America, the survey notes, farmers are more willing to spend on agtech if it helps them deal with real threats. Now, researchers around the globe are answering the call, developing novel approaches to help farmers catch pathogens before disease takes hold.

“It really feels like researchers are starting to understand that plants are the ultimate storytellers of what’s happening in the field,” Hunnicutt said. “If we can figure out how to read that story, we can respond not just faster and more effectively, but in a way that’s more sustainable. With tech like this, it’s not just about spraying because it’s that time of year. It’s about knowing whether you actually need to. Otherwise, you’re throwing money away and doing more harm than good to the soil and the plant.“

“The Ultimate Storytellers”

Catching disease before it takes over a field is the golden fleece for farmers. Many still rely on sight alone to spot the blight, but by then, it’s usually too late. Losses can be devastating. For Hunnicutt, a pathogen can wipe out up to 50 percent of a crop, or $350 an acre. He says that even an 8 percent loss costs $50 an acre. As sustainable agriculture advocates push to cut fungicide use, early detection tools make targeted treatments possible. Basically, farmers can spray only when there’s an actual threat and not “just in case.”

In California, InnerPlant co-founder Shely Aronov said the team decided to target fungus first because it’s invisible, making it “the hardest stress.” Figuring out how to make a plant fluoresce was a multi-step process. By comparing healthy plants to sick ones, molecular biologists observed which plant genes switch on when stressed. Then they hooked those stress switches to a glowing protein and put it back into a healthy plant so it lights up when under attack.

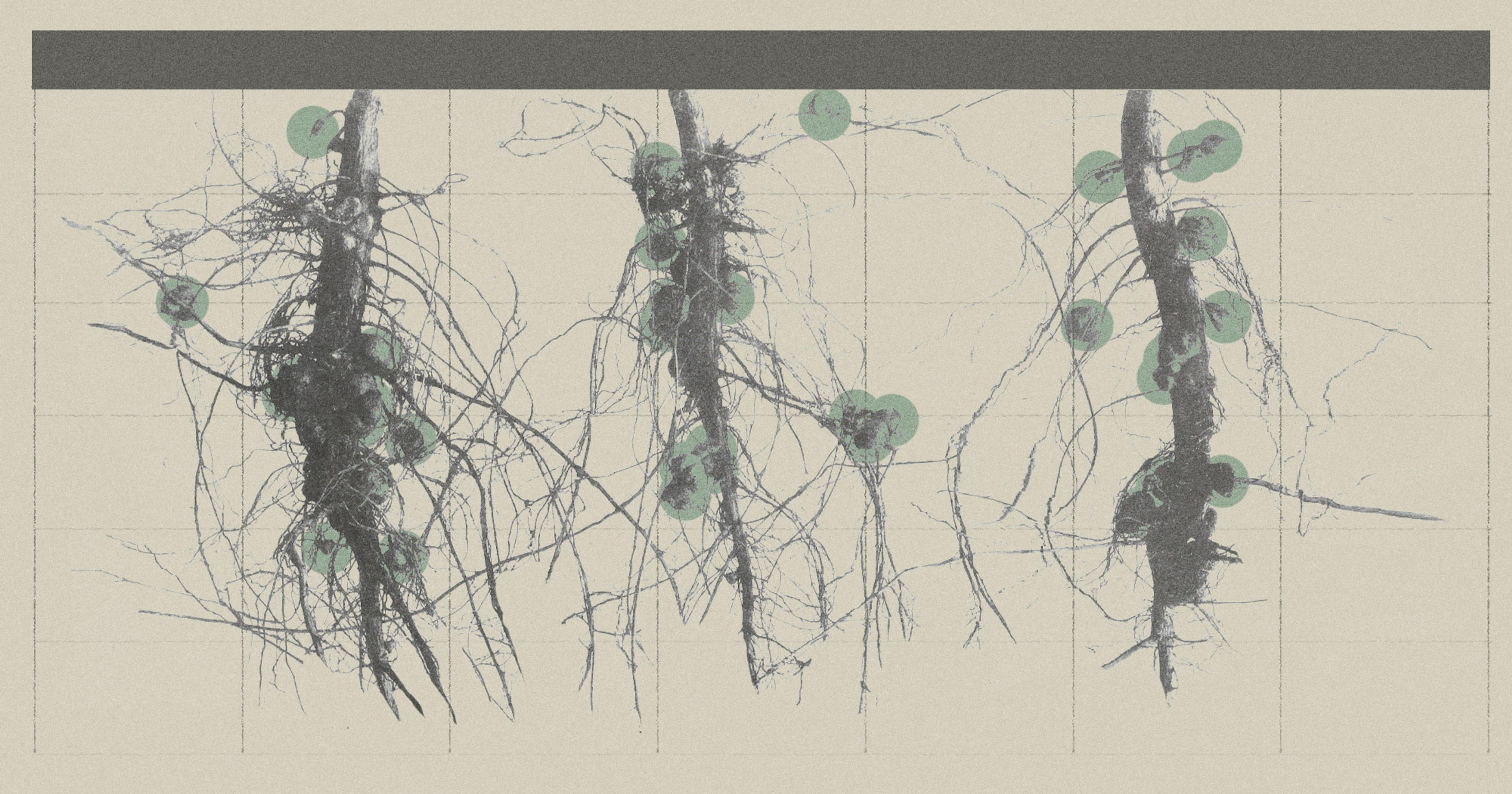

Across the country, researchers at North Carolina State have zeroed in on volatile organic compounds (VOCs) to decode what plants are saying.

“Plants do not talk, but they do emit small molecules to communicate,” said Qingshan Wei, lead developer and associate professor of chemical and biomolecular engineering at North Carolina State University. “Sometimes, when the stress comes in, plants release those molecules as a warning to neighboring plants.”

The idea was simple: If Wei’s team could learn to read those VOCs, they’d get an early heads-up too. Rather than relying on bulky lab equipment to extract DNA, Wei developed a “Fitbit for plants.” Weighing just 1 to 2 grams and no bigger than a postage stamp, the sensor attaches directly to a leaf and detects VOCs emitted during the early stages of a pathogen attack.

Early lab tests on tomato plants showed promise detecting multiple pathogens earlier than usual tools, said Zach Hetzler, a postdoc at NC State and CEO of Verdia Diagnostics.

The team is now moving into pilot trials, ultimately aiming to deploy a distributed sensor network across a field or greenhouse. Though pricing is in the early stages, Hetzler said they’re aiming for about $30 per sensor. This is low for greenhouse growers, he added, especially given the potential to save about 50 percent more plants compared to relying only on visual cues.

“We are inspired by a lot of the existing systems in nature,” Wei said. “Some animals, like a mouse or dog, can sniff out diseases — some plant diseases, even some human diseases. The mechanism behind this is still not clear, and for us, that’s also quite a motivation. If natural living systems can perform so well, can we, as engineers, create something that does the same thing?”

Reading the Air

Across the pond in the UK, instead of targeting VOCs, researchers at the Natural History Museum and the Earlham Institute have their sights set on spores.

Matt Clark, lead researcher at the museum, developed a technology called AirSeq (pronounced “seek”), which captures spores using a vacuum-cleaner-like filter system. The particles are then flushed out, processed and run through a nanopore sequencer, a USB-stick sized device that can decode full genomes on the spot.

In greenhouse trials, he said, AirSeq detected fungal diseases in strawberries two weeks earlier than agronomists could. He envisions the tech evolving into a small device farmers place in their fields for real-time monitoring, combining spore readings with existing weather data to backtrack where the spores are coming from.

But something of this scale would require government backing and, of course, money. Previously, Clark received funding for biodefense applications from the Defense Advanced Research Projects Agency (DARPA), but that ended. To build the automated prototype, the team needs more financial support, he said, citing estimates in the low millions (USD).

Sequencing entire genomes gives deeper insights than a single-gene test, but requires more complexity. On the hardware side, the box needs to be either mobile (like a self-driving vehicle or drone) or large and bolted to something big, so it’s not left unattended for long periods or too hard to steal. The device also needs to be cheap enough for farmers to afford running it, but he believes it would help pay for itself by reducing pesticide use.

Ideally, the box would be inexpensive, initially around 10,000 GBP, he said. But scaling and a suitable service model could help bring the price way down. One idea is to create a monitoring system paid for by a mix of levies (small fees UK farmers and co-ops pay based on crop production) and local or national government money.

“As the data can inform all farmers in an area,” Clark said, “this is a way for all to benefit but keep the costs (per farm) low.”

Old Farm, New Tricks

Financing is always tricky, but farmers know that growing anything is about learning the right balance. Hunnicutt understands this, especially when it comes to irrigating soybeans when fungus is present. Too much water feeds the white mold. Too little makes the soybeans suffer, and yield drops. He knows a farmer who faced this exact dilemma last year.

Row spacing also adds to the complexity. Wider 30-inch rows improve airflow, which helps the canopy dry and slow mold growth. But as plants close in, moisture gets trapped, and mold thrives.

In both cases, catching stress two weeks earlier means treatments can be applied to prevent damage.

These challenges aren’t new. His father and grandfather dealt with them. But while the problems remain, the tools to counteract them keep advancing. Overall, he said, his father and brother support innovation, at least once he explains what the new technology can do.

“Usually the question is ‘Why?’ and I just say, ‘Why not?’” Hunnicutt said. “We’ll try it. If it doesn’t work, we’ll learn something anyway.”

One afternoon in May, the InnerPlant team planted a sentinel plot — designated plantings used as an early warning system — in his 160-acre field to signal a potential fungal outbreak. In August, despite the high humidity (where white mold usually thrives), nothing has shown up. No signal, no stress. Nothing.

“We haven’t seen any results,” Hunnicutt said. “I keep waiting to see if anything pops on ours. If it doesn’t show up, that doesn’t mean the technology doesn’t work. It just means we don’t have any disease … Maybe we just lucked out. I don’t know.”