To make money farming native seeds and plants, commercial growers must navigate a myriad of challenges unique to the industry.

Of all the native plants he grows, Nicolas Lirio’s favorite is rough blazing star, a prairie plant bearing tall stalks festooned with tufts of wispy purple petals. “We don’t make any money off of those fields, but I emotionally keep those fields around,” Lirio said. He grew up on a prairie farm in Iowa, and his dad started Hoksey Native Seeds, a commercial native seed farm which Lirio now runs.

Lirio isn’t alone: Commercial native seed and plant suppliers must balance business realities with their passion for natives, plants that have evolved over a long period of time within — and therefore are uniquely suited to — a specific area’s environment and ecosystem. But that is just one challenge. As these growers strive to make a living, they must navigate and adapt to a host of hurdles inherent to the world of native plants.

These plants are crucial to the survival of a local ecosystem. Over time, they become so intertwined with that ecosystem that their demise threatens the survival of the system as a whole. For instance, the loss of a native plant species threatens the survival of the insects that eat that species as well as any birds that eat those insects and so on. When natural disasters such as wildfires or floods decimate habitat, those working to restore the land must have native plants to halt this domino effect. If they tried to use non-native plants instead, those plants may not be able to fulfill the natives’ role since they didn’t co-evolve with the rest of the ecological community.

This need for natives is only expected to grow, but demand has already outpaced supply. The fragmented, temporary, and reactionary nature of our current native supply chain is a major cause of the deficit. When combined with other obstacles in every stage of production, these problems are often too much for a commercial grower trying to make a profit supplying natives.

Lirio summed up life as a commercial native plant grower. “Natives are uncertain. Like with corn and beans, you put stuff in the ground, you know what’s going to come up,” he said. “You’re going to make margins that are thin, but they’ll be there, and you’ll have support from all sorts of people around. With natives, it’s like, sink or swim.”

Ed Toth has spent his career growing and studying native plants, currently leading the nonprofit Mid-Atlantic Regional Seed Bank. Toth believes that commercial growers are just as important to solving the problems of native seed and plant supply as other entities. Growers of all sizes — commercial and nonprofit — must work together. “It’s not one or the other. It’s all of them, and it’s about them all finding their niche in the overall supply chain.”

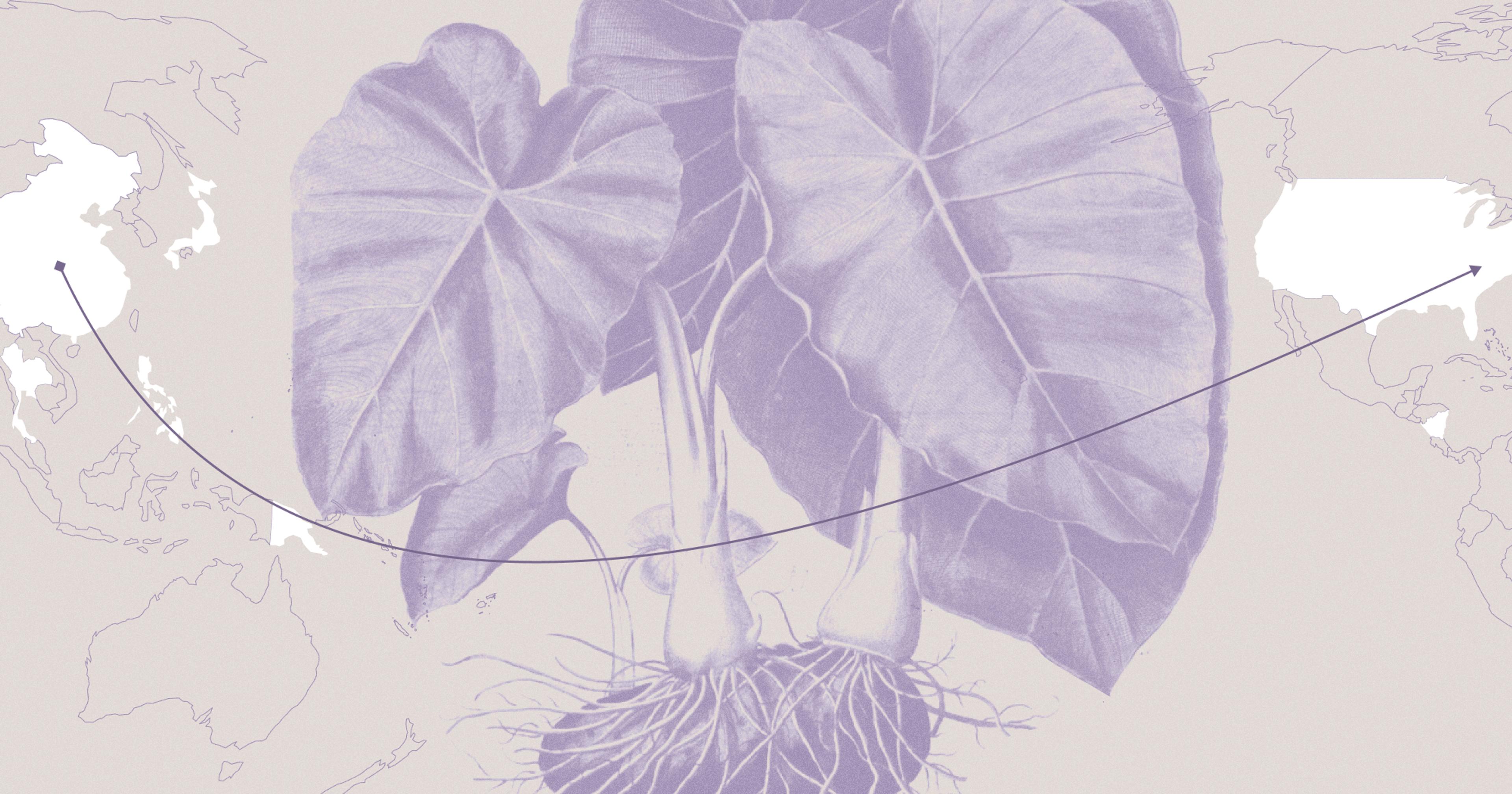

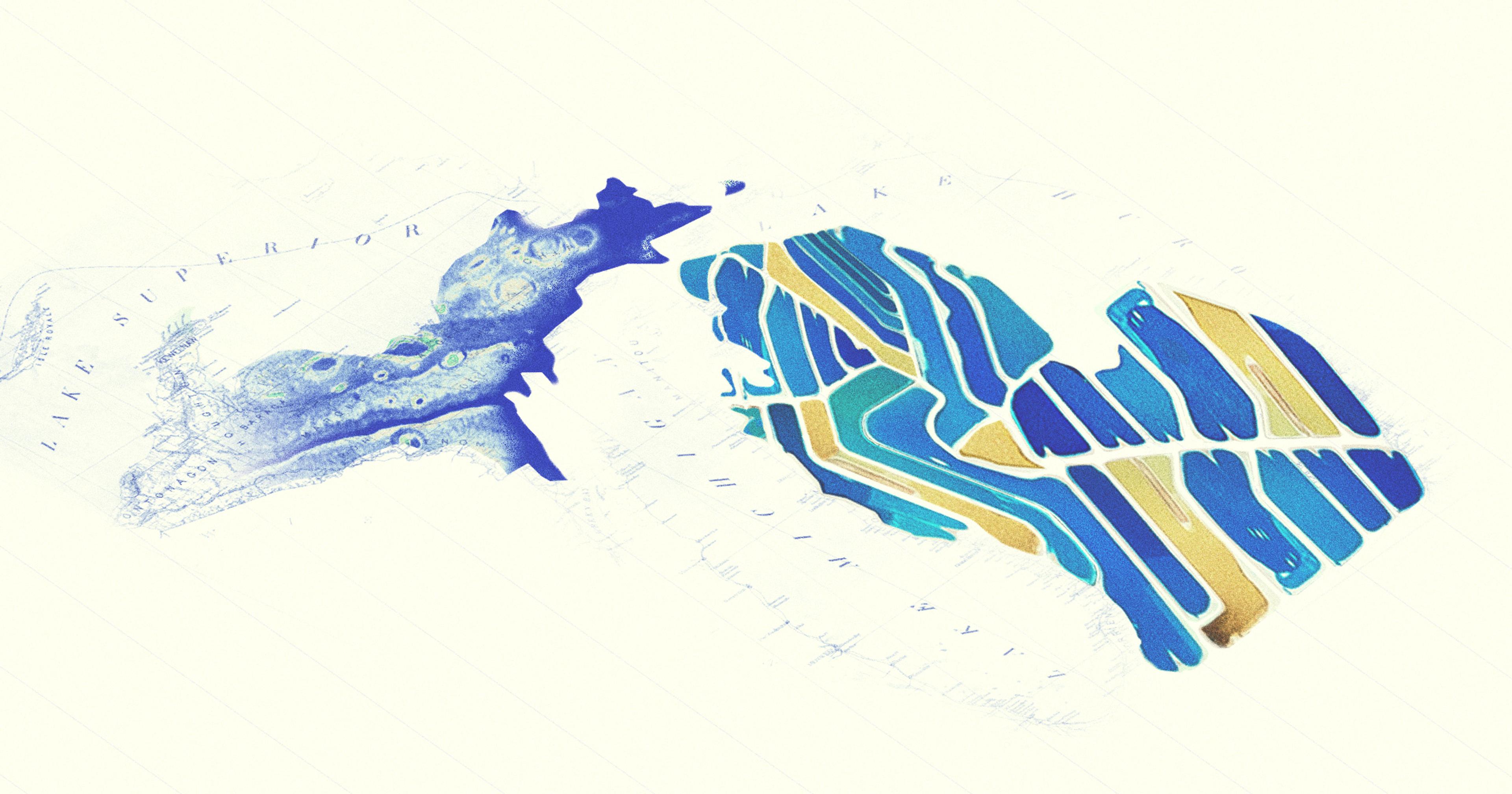

Commercial native plant growers already exist within a niche. This is because what’s native in one region may not be in another. This limits their customer base. “We only ship to states that we feel it’s appropriate that our seed is in,” said Lirio. So commercial native growers must search for customers — individuals, nonprofits, other businesses, or government agencies — within these layers of limitations. The customer must be in the right geographical area, they must be searching for native instead of non-native plants, and they must be interested in the specific species sold by that grower.

But Toth is referring to an even more specific niche: a particular supplier’s specialty within its region’s native plant world. When businesses find that niche, they mimic the evolutionary history of the native plants they sell. They ensure their companies’ survival by adapting to the demands of the market while also becoming essential providers to others in the industry. Commercial growers must be flexible; there is no one business model for success.

“With traditional marigolds and hostas, [when] you’re running low, you know where to get more. That doesn’t happen with what we carry.”

Tom Knezick knows firsthand the importance of finding your niche. He is the president of Pinelands Nursery & Supply in New Jersey, a wholesale native nursery that grows live plants to sell to other businesses. After Knezick and his team calculated their administration costs per order, they decided to implement purchase minimums, including requiring customers to buy a set number of plants per order. Since they applied these restrictions, their business has grown.

Prairie Moon Nursery in Minnesota has the opposite business model. It sells to everyone, individuals included. According to Becky Klukas-Brewer, Prairie Moon’s director of marketing, sales, and service, their specific retail approach works because of the company’s scope. They sell mainly through their website to a large number of customers and offer a lot of species. While other nurseries might offer one or two hundred species, Prairie Moon offers more than 700.

In addition to disparate business models, growers’ experiences with native growing patterns can differ. Both Hoksey and Prairie Moon grow species in separate fields to farm them efficiently. While Prairie Moon’s Klukas-Brewer has not observed any adverse consequences of growing monoculture plots, Lirio said this quickly depletes the nutrients in Hoksey’s soil — ultimately shortening the lifespan of fields.

Native plant farmers must also take the idiosyncrasies of various species into account when planning their finances. For instance, both Prairie Moon and Hoksey grow whorled milkweed. While Prairie Moon has not had any trouble with this species, Lirio at Hoksey knows he will have to invest years of resources into the field; he hopes he can make his profit for the endeavor in perhaps a single harvest. He attributes this to a toxin released by the plant to ensure nearby plants can’t overgrow it. Since it’s grown by itself, it suffers from its own toxin, shortening its lifespan.

Native farming is also complicated by customer demands that reveal a general unfamiliarity with native plants. “There’s a seasonality to it,” Knezick said. “It’s not like other manufacturing.” Growers must wait for the correct season to plant the seed they have, then wait until they can harvest more seed from those plants, and wait for the next appropriate planting time to repeat the process until they have the required amount of plants or seeds. It might take years to produce that amount, but often customers, including government agencies requesting bids on contracts, want delivery on an impossibly short timeline.

“There’s not many people that do what we do or have the same goals that we do, so we have to do a lot of it ourselves.”

Klukas-Brewer has noticed that native plant trends can clash with native market realities. At one point, she and her team received requests from engineers and landscape designers hoping to create lawns of Pennsylvania sedge, a native in her region that looks like grass but requires less maintenance. But since it’s difficult to grow, the seed didn’t exist in the amounts requested. “I mean, certainly garden centers and nurseries are dealing with live product, but a lot of time with traditional marigolds and hostas, you’re running low, you know where to get more,” Klukas-Brewer said. “That doesn’t happen with what we carry.”

This lack of easily accessible materials means that native growers must be self-sufficient. “There’s not many people that do what we do or have the same goals that we do, so we have to do a lot of it ourselves,” Knezick said. When he and his team realized they needed a reliable supply of seed for their business, but unlike a traditional nursery where consistency among plants is key, they began looking for genetic diversity. That way, the plant’s population would be better able to survive to fulfill its role in the ecosystem including as food for wildlife and a method of erosion control. So to get the appropriate seed, Knezick and his team began collecting it from partners’ properties. When customers began asking to buy the seed they collected, they decided to expand, raising some plants exclusively for seed sales.

The Hoksey Native Seeds team is used to finding creative solutions on their own. Over the years, the company has had to modify old combines and tractors because the equipment they needed wasn’t manufactured. They’ve also created their own native seeders, machines that plant seeds in fields, which they’ve rented and sold to customers. With traditional seeders, prairie seeds are sown in unnatural rows and can get stuck in seeders’ tubes, but Hoksey’s seeders have eliminated these issues.

Lirio attributes this lack of specialized equipment to a lack of investment in the industry. But like a native plant species evolving to become the sole food source for a local insect species, perhaps the Hoksey team has discovered a gap in the industry they can fill. And their success — as with that of all commercial native seed and plant growers — doesn’t just ensure their future. It’s also key to the future of the natural ecosystems surrounding us.